Type: 21NG-A(BTLY)

Voltage: 0.6/1kV

Features: 具有良好的机械性能,电气性能和耐化学腐蚀性能,还具有结构简单,重量轻,敷设不受落差限制等优点。

Application: 广泛用于城市电网、矿山和化工厂等地方。

在过去15至20年来交联聚乙烯绝缘电缆的需求迅速增长,这种类型的电缆已成为电力电缆的主要类型。

胜宇电缆积极开发和应用交联聚乙烯绝缘电缆zui近的制造技术,并一直在不断努力获得更多的从事质量稳定,并产生更高电压的交联聚乙烯绝缘电缆(超过500千伏)。

本产品适用于固定敷设在交流50Hz, 额定电压35kV及以下的电力输配电线路上作输送电能用。与聚氯乙烯绝缘电力电缆相比, 交联电力电缆产品不仅具有优异的电气性能、机械性能、耐热老化性能、耐环境应力和耐化学腐蚀性能的能力,而且结构简单,重量轻,不受敷设落差限制, 长期工作温度高(90℃)等特点。

执行标准:GB/T12706.1-2008

| Type Cu、Al | Specifications | Core NO. | Voltage |

|---|---|---|---|

| 21 | 12 | 12 | 12 |

| NG-A(BTLY) | 2.5~6mm² | 3~61芯 | 0.6/1kV |

| 补充说明:

导体规格120mm²及以上建议选用单芯电缆,以方便敷设。 | |||

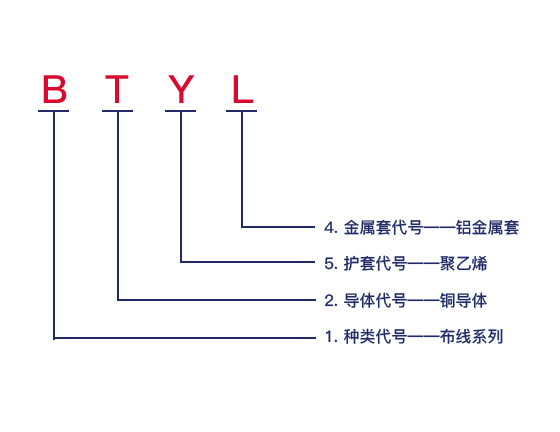

耐火Nnn

隔离G

等级A(950℃~1000℃)3小时

布线系列B

铜导体T

云母绝缘省略

铝金属套L

铝合金金属套LH

铜金属套T

铜合金金属套TH

聚乙烯/聚烯烃Y

隔离型(柔性)矿物绝缘电缆,额定电压0.6/1kV,4芯,标称截面120mm²,表示为:

NG-A(BTLY) 0.6/1kV 4×120

隔离型(柔性)矿物绝缘电缆,额定电压0.6/1kV,1芯,标称截面240mm²,表示为:

NG-A(BTLY) 0.6/1kV 1×240

可简称为NG-A或BTLY,又称NG-A(BTLY)、WDZAN-BTLY、WDZAN-BTLV、BTLV、BTLYQ、BTLVQ等。

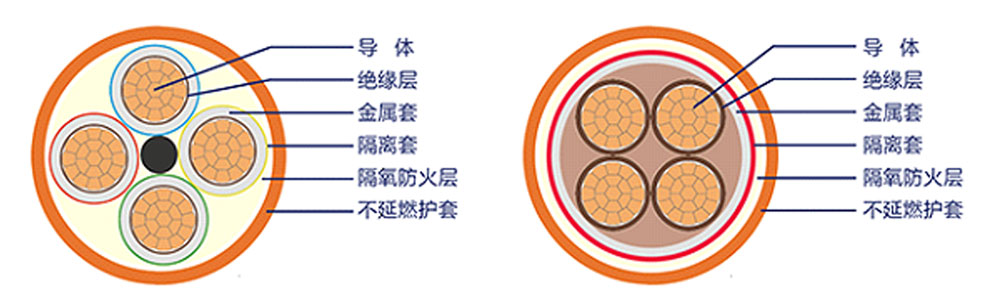

1. 导体:采用多股铜线绞合而成,具有良好的弯曲特性。

2. 绝缘层:采用矿物质绝缘材质。

3. 金属套:采用铝质软护套,经特殊工艺加工处理,具有良好的导电性能、抗机械撞击力、柔性弯曲等特性(可代替地线)。

4. 隔离套:采用交联聚乙烯防水隔离层。

5. 隔氧层:采用Mg(OH)2或Al(OH)2矿物质材料,具有耐高温、防火性能。

6. 外护层:采用低烟无毒或更好更高的塑性材质,有良好的防腐蚀特性,可根据要求选择不同标号的材料。

敷设施工方法

1、将电缆盘放在放线架上(通常电缆盘放在楼下,将电缆提拉上去)。

2、提升用的绳索通过卷绕机与电缆相连接,开动卷绕机将电缆提升上去。

3、提升用的电缆网套到达房顶时,将网套挂在事先准备好的吊钩上。

4、对中间部位进行固定。

5、将分支线端头与电流表或断流器相连。

6、进行与横向干线或主干线版的连接。

施工中注意

1、确认预制分支部分是否能安全通过贯通孔洞;

2、采取预防措施,防止提升过程中分支部分被贯通孔洞损伤;

3、提升过程中不要对分支电缆施加张力;

4、使用提升用绳索的强度应为电缆重量的四倍以上;

5、电缆提升完毕后,应立即用适当的方法加以固定,以免电缆脱落受损;

6、单芯电缆禁止使用铁质夹具。

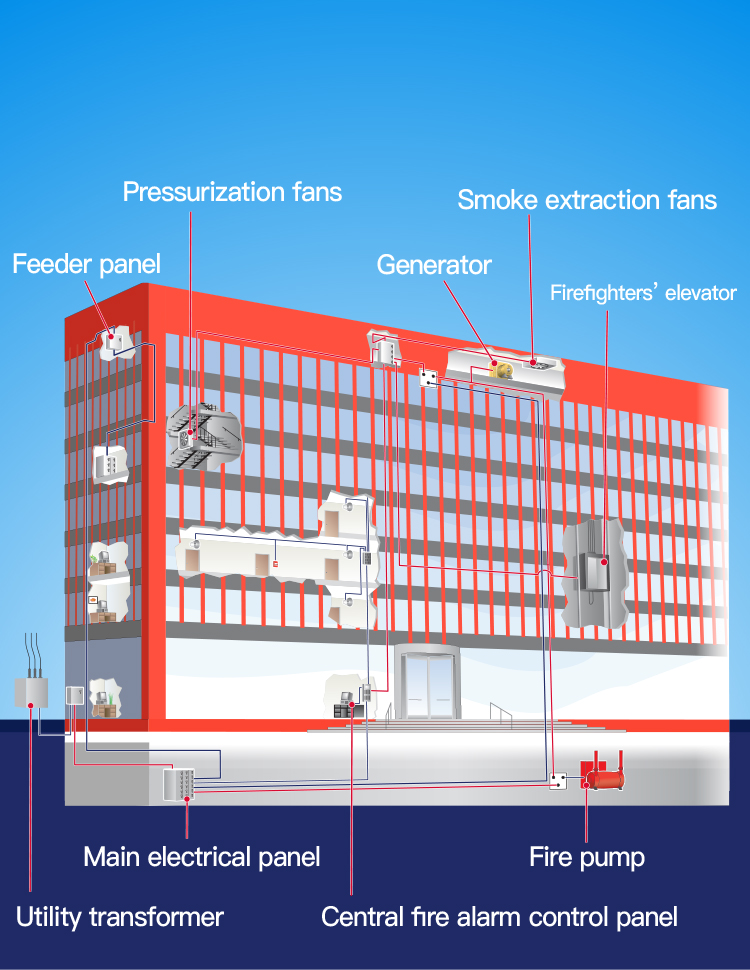

·Hospital operating rooms

·Air pressurisation system for stairwells

·Fire alarm systems

·Emergency power systems、Emergency lighting systems

·Sprinkler systems

·Public buildings e.g. theatres, cinemas, hotels, schools

· Tunnels and mines

· Temperature measurement devices; RTD's, thermocouples

· Close to or inside industrial foundries, kilns

· Hazardous areas where flammable gases may be present

· Transport hubs - railway stations, airports etc

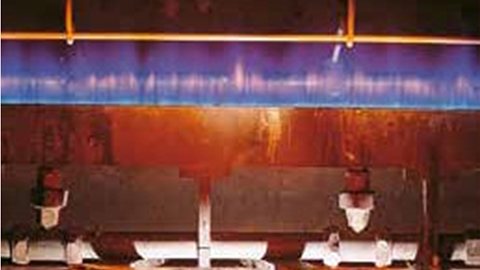

Fire Performance BS 6387 Performance Requirements for Cables Required to Maintain Circuit Integrity under Fire Conditions.This standard details the following tests to categorise cables according to their fire withstand capabilities.

The cable is tested by exposure to gas burner flames while passing a current at its rated voltage.

Four survival categories are defined in the Performance Table below.

A new sample of cable is exposed to flames at 650°C for 15 minutes whilst passing a current at the rated voltage and then the spray is turned on to give exposure to both fire and water for a further 15 minutes.

The grade results are as follows:

The final requirement is mechanical shock damage. A fresh sample of cable is mounted on a backing panel in an S-bend and is exposed to flames whilst the backing panel is struck with a solid steel bar the same diameter as the cable under test every 30 seconds for 15 minutes.

Whilst the cable has been exposed to temperatures as defined in the Performance Table below.

Sunwin MI Cable can easily comply and withstand the most onerous categories of C, W and Z using one single Cable Sample